Story of the Month

Turn Your Trash into Treasure

American Supply has dedicated its path to seeking out and pushing innovative practices since 1948. Our continuing quest for innovation focusses on sustainable materials and durable technical solutions – those that strain the environment as little as possible during their production, use, transformation, or disposal – and our commitment to the tenets of sustainability and eco-innovation in the future is paramount.

After three months of lockdown, the deconfinement has us taking cautious yet affirmative steps back towards normality and getting ready to experience our city revitalized and the ‘new normal.’ We, like you, have been in an introspective frame of mind, with a desire to better our practices and our product offer and we want our vision to meet your future needs. Coming out of confinement, we have seen a convergence of focus on local products and local markets. Our office in central Paris is in the heart of Europe, which makes us perfectly placed to react to the needs of clients from all over the continent with rapid response times with efficient material and production solutions.

With this in mind, we are proud to introduce a new thermoplastic raw material at American Supply – Ubiplast™. Ubiplast™ is produced from 100% domestic waste, using an innovative new process; therefore, it reduces potential harmful landfill and is an essential infinitely renewable resource for the planet and you.

Ubiplast™ comes in pellet form and can be used in manufacturing processes in injection, extrusion and compression moulding. It can be mixed in varying percentages with olefin, styrene and chlorine-based resins and additives, which all impact differently on the final carbon footprint. When used in as little as 10% of the final mix, it makes the final product Carbon Neutral, and if used in 20% the final product becomes Climate Positive. We are very proud to offer this innovative product, as it is truly a breakthrough for the plastic industry and the environment – we can now turn our trash into treasure!

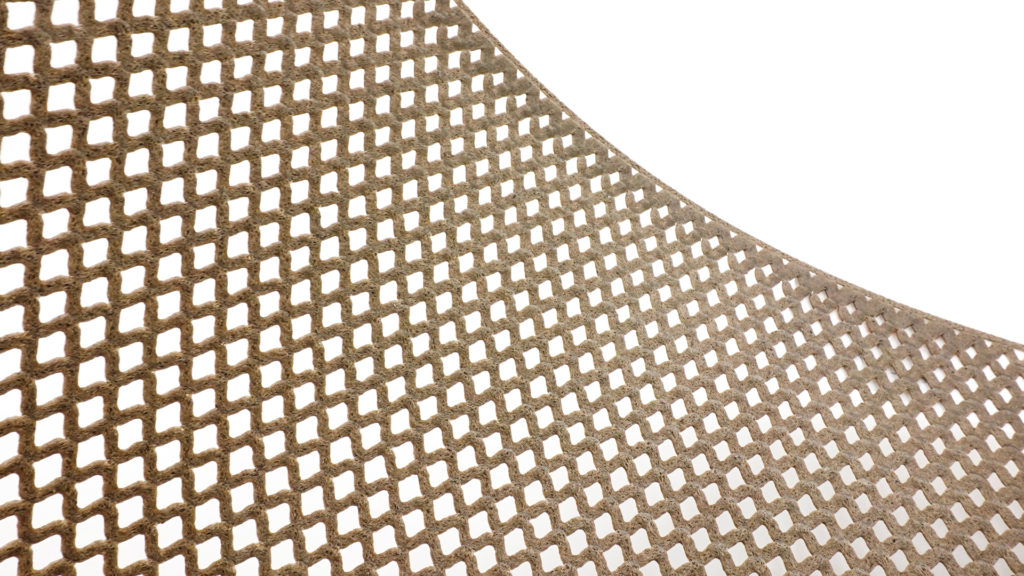

We have produced several tests using natural coloured pellets in a 3D printer, using a mixture that incorporates 20% Ubiplast™ making the final printed product Climate Positive, in its neutral colour. We have experimented making sculptural forms and a flexible mesh, which can then be sanded and painted in eco-friendly paints. These examples are just the tip of the iceberg of possibilities! With our 3D printing capabilities, we can produce sculptural elements for your projects up to 1.5 metres by 1.5 metres in size, making Ubiplast™ an eco-innovative choice for all luxury Merchandising and PLV.

We are also currently developing an exclusive range of ready-to-use sheet materials that can be applied to your fashion, design and merchandising projects that will be revealed soon. We can also accompany you to develop bespoke materials and applications that will make your material solutions climate positive and more environmentally friendly.

We look forward to working with you on your upcoming projects, incorporating this wonderful new eco-innovative material, making the Material World a more conscious, eco-friendly place!

Contact a material expert to learn more about how Ubiplast™ can enrich and benefit your creative projects.