Story of the Month

Concrete

Crush

After several delays due to the pandemic, the Pinault Collection has finally opened its doors in the iconic Bourse de Commerce building in central Paris. Since building work began in 2017, we were eager to see how one of our favourite architects, Tadao Ando, would re-imagine the space whilst keeping the building’s historical details and highlighting the impressive Pinault art collection.

Another big Concrete story in the news this month was the completion and inhabitation of the first 3D printed concrete house in Europe. With its whimsical sausagey appearance and soft lines, it feels at once both futuristic and prehistoric. Composed of various parts that were 3D printed off-site before being assembled together on-site, it is the first in five houses that are planned in the city of Eindhoven (The Netherlands) as part of ‘Project Milestone’.

From Project Milestone’s Website

In 3D printing, the concrete used is optimized as it is able to be applied and layered where it is specifically needed for form and construction, unlike poured concrete which must be solid and uses a lot more primary material. The more concrete that is used, the more CO2 emissions are released, as greenhouse gasses are released when concrete is produced, so this new method is both energy-efficient and more environmentally friendly.

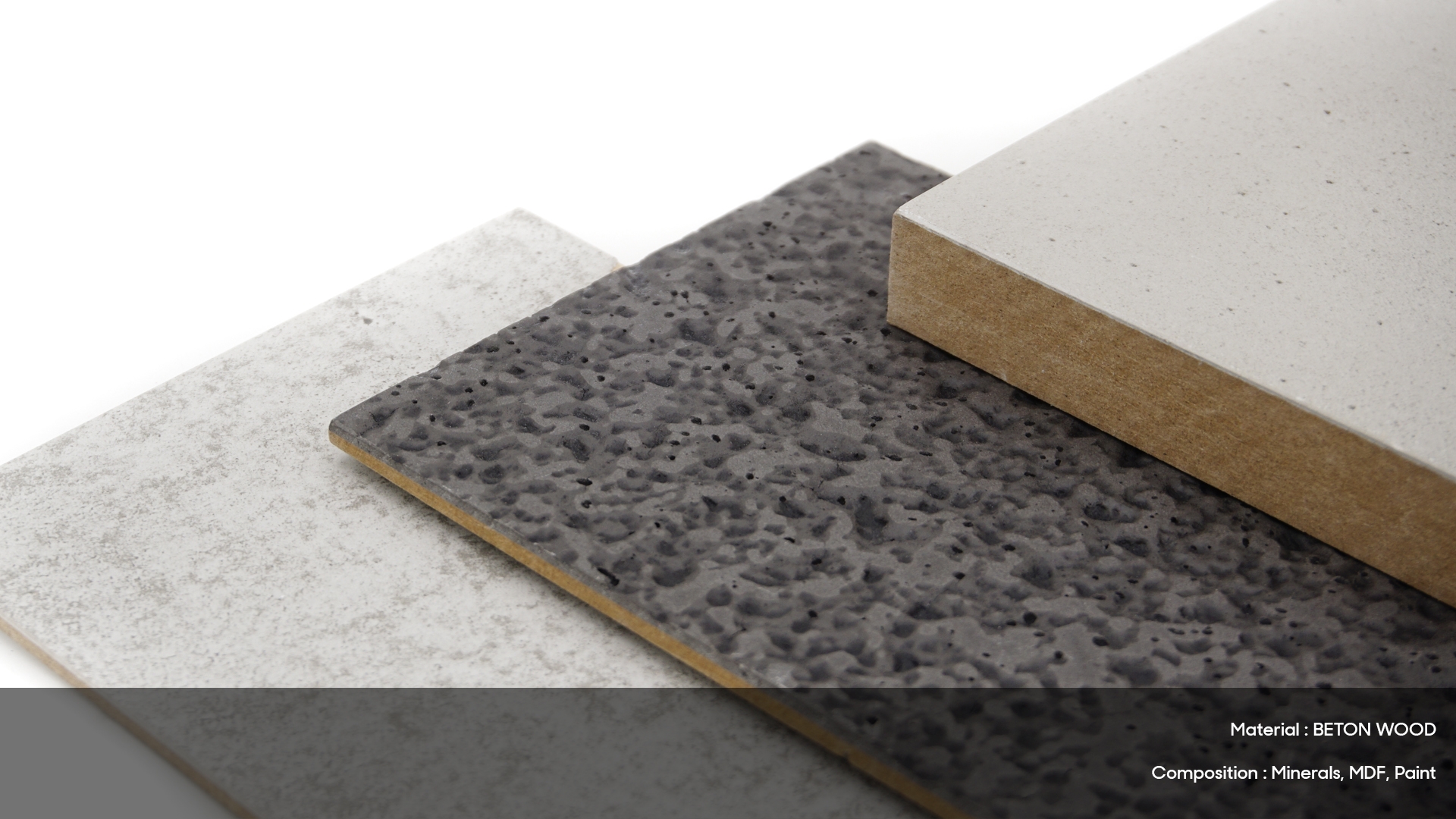

Here at American Supply, we have many different concrete-effect materials in our collection that give you the look and feel of concrete without the weight, environmental impact, and complications of their application, making them perfect for forward-thinking merchandising and POS solutions. These materials allow you to achieve the beautiful aspect of concrete without using massive amounts of raw materials and can be used for temporary or permanent applications depending on your needs.