TECHNOLOGY

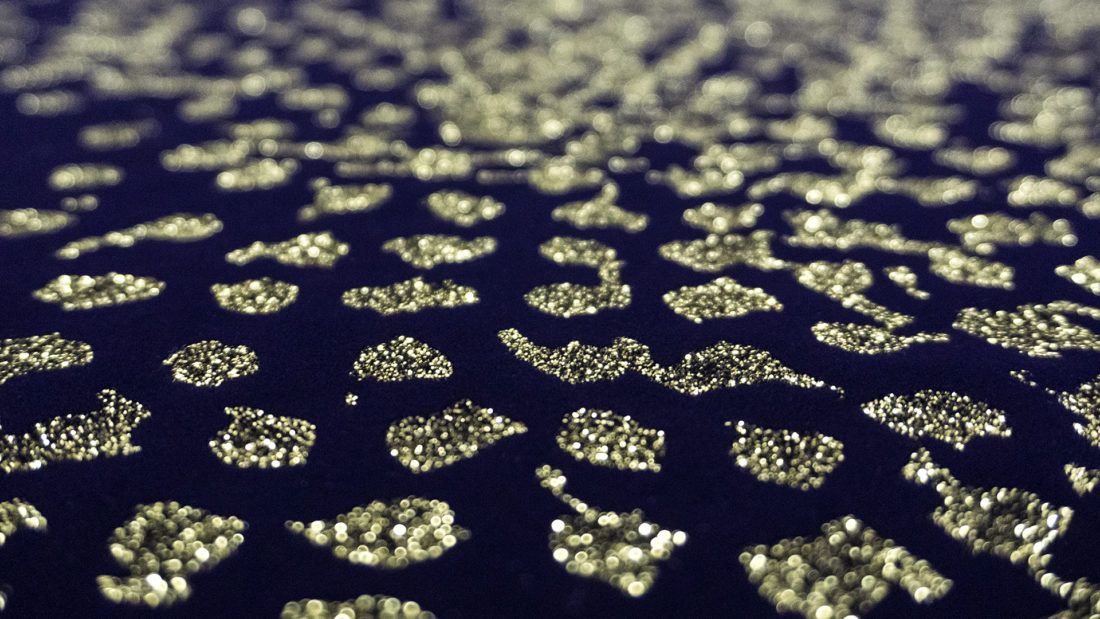

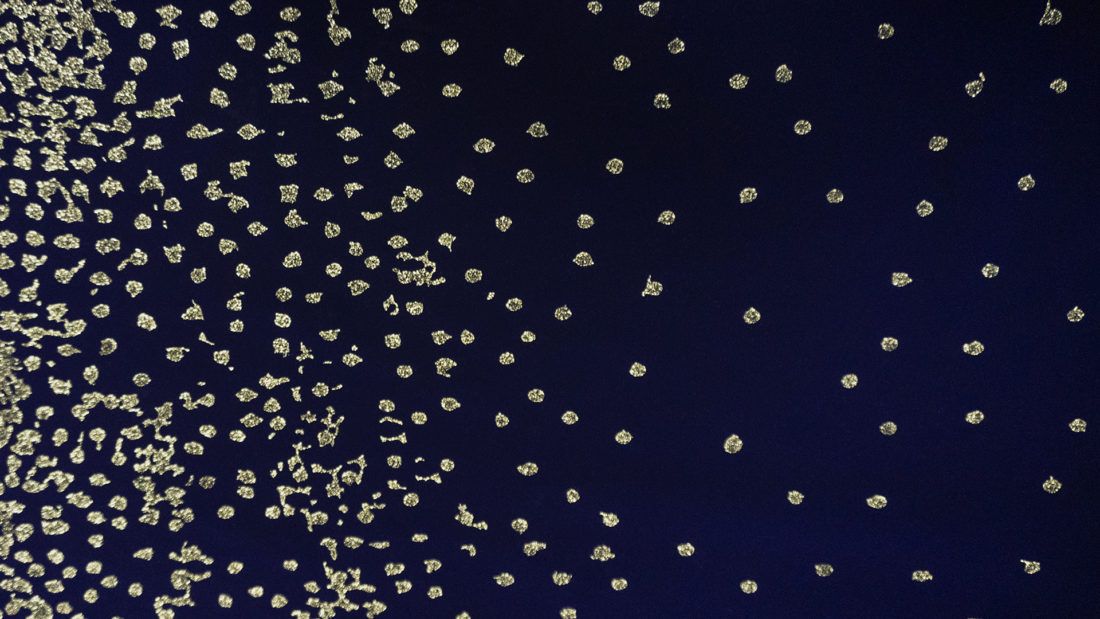

Large-Scale Glitter Projection Printing

The usual process for screen printing with glitter requires the glitter to be mixed with a transparent varnish that saturates it before it is printed on the surface. With this method the metallic appearance of the glitter is lost and replaced with a more plastic reflection, making the effect less interesting: the glistening metal is not only drowned in the varnish, but the size of the glitter is also limited by the weave in the silkscreen. With our new exclusive development, we give back to the glitter its glistening potential and elevate it with the ability to vary particle size and allow a more anarchic placement on the surface, letting it shine in all directions.

American Supply’s Creative-Techno-Lab is the only team in Europe that can achieve Large-Scale Glitter Projection Printing of 140cm wide by 250cm long in a wide range of Glitter references and in any custom design. For the example shown above, we projected a custom Large Hexa Glitter in a Snowfall design, printed on our Deep Blue luxury velvet.

This technique can be applied to a wide range of fashion, design, and visual merchandising applications. Imagine what you could achieve with this new large-scale format.

American Supply continues to push the material boundaries both technically and creatively with our in-house expertise.

Credit Photo: American Supply